Design Fmea Is Used for Which of the Following Scenario

Design FMEA DFMEA is a methodology used to analyze risks associated with a new updated or modified product design and explores the possibility of productdesign malfunctions reduced product life and safety and regulatory concernseffects. Before developing system control plans for both existing and new processes.

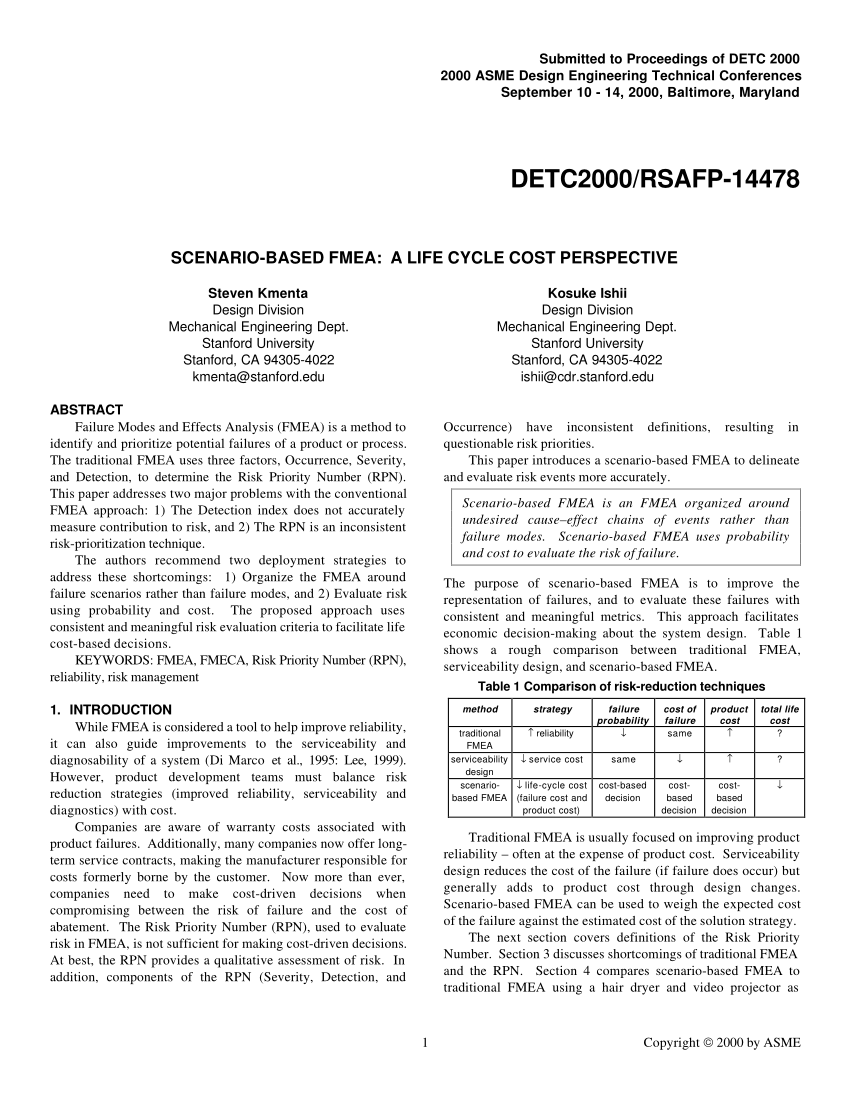

Comparison Of Risk Reduction Techniques Download Table

Swimming with the appliance biological hazards hazards with the device failing due to water ingress etc spilling a variety of liquids Cokes oils juices etc on the device.

. Choose the simulation strategy 3c. The goals of FMEA are to. Identify steps in the process 13.

Depending on the product the company or the analyst it can present different structures. Define the process 7 Step 2. At this point designer would have to review the historical problems or complaints encountered and perform necessary analysis before proceeding with newimproved design.

An FMEA is used to structure mitigation for risk reduction based on either failure mode effect severity reduction or based on lowering the probability of failure or both. Business operations environmental services and others. Ideally DFMEA is done for products before they reach production 2.

Then it helps you take steps to mitigate or reduce their negative outcomes. The following major types of FMEA are commonly used based on the application. The possibility of use of Failure Mode and Effect Analysis methods is connected with continuous quality improvement of organization.

Identify ways in which a product may fail. Describe the scenario 3b. The breakdown can be as detailed as you like.

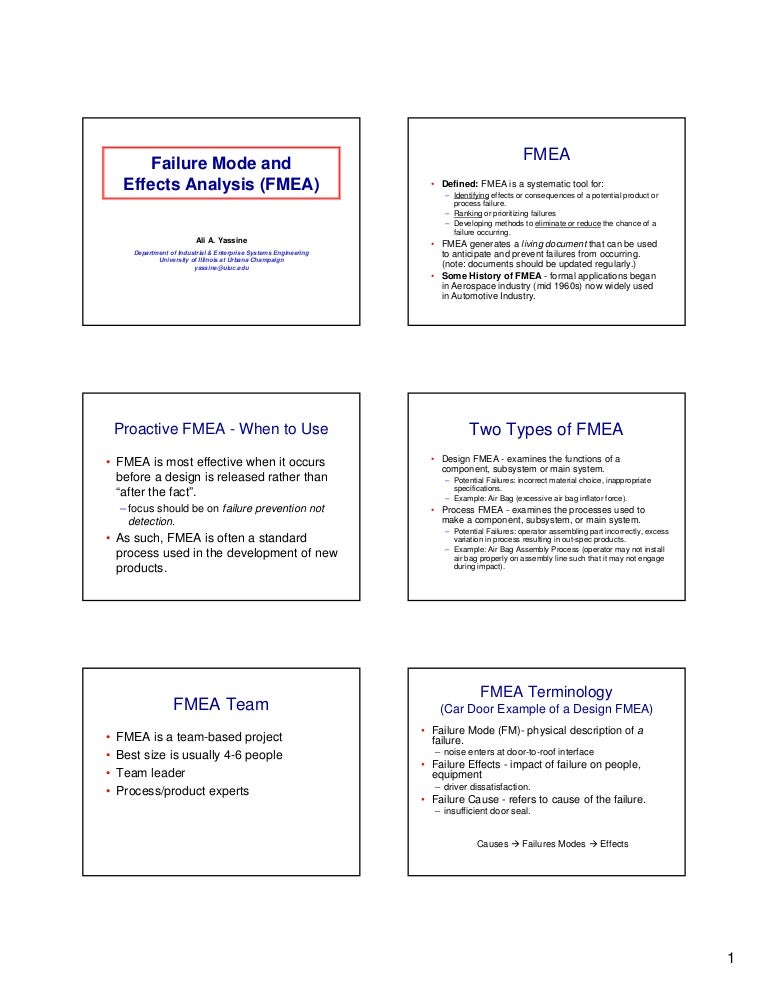

B Process FMEA PFMEA focuses on potential failure - modes of products caused by manufacturing or assembly process deficiencies. The FMEA or F ailure M ode and E ffects A nalysis is a process that helps defining and designing products by focusing on what might fail before releasing their final versions. There are currently two types of FMEA.

By using inductive reasoning to assess failure risks in a process or products design and development FMEA makes good engineering even better. Design FMEA DFMEA In DFMEA analysis is done on basic properties of a product like material geometry etc. Your team can use FMEA to evaluate and prevent possible failures by correcting early rather than reactivelyafter failures have occurred.

You can use FMEA to examine processes in any of these areas to proactively reduce risks to patient safety and improve quality of care and quality of life for residents. Referencing ISO 90012015 risk-based thinking this course demonstrates the basics of creating a Design FMEAa critical step in assessing risk to the development of a product and the business. Design and execute simulation 11 3a.

Design FMEAs or DFMEAs enable you to assess and address potential failure modes during the early or end stage of product design. A couple of the use scenarios included. The methods and techniques associated with the FMECA were published in a.

Bumping into things device could bend break additional damage to the bones. However there are 3 main pillars every FMEA process should have. The FMECA involves creating a series of linkages between potential failures Failure Modes the impact on the mission Effects and the causes of the failure Causes and Mechanisms.

Process FMEA PFMEA PFMEA is done for analysis of manufacturing and assembly processes. There are mainly two types of FMEA 1. Before launching a new product process or service.

Failure Mode Effects Criticality Analysis FMECA is a method which involves quantitative failure analysis. The FMEA is in principle a full inductive forward logic analysis however the failure probability can only be estimated or reduced by understanding the failure mechanism. Assemble the team 9 Step 3.

This process is not a closed framework. Design FMEA DFMEA and Process FMEA PFMEA. While making improvements to existing processes products and services.

DFMEA explores the possibility of malfunctions reduced product life and safety or regulatory concerns. Monitoring in organization using Failure Mode and Effect The FMEA is a design tool used to systematically analyse Analysis method has been presented. FMEA is classified into 2.

Design FMEAs DFMEA enables organizations to assess and address potential failure modes are the early or end stage of product design. FMEA Four separate and independent types of FMEA Design FMEA Focus on the product development and design process Process FMEA Focus on the manufacturing production office or healthcare process Application FMEA Focus on. The analysis can be qualitative or quantitative.

Organizations perform DFMEA in the following scenarios. Major medical center power failure MRI Incident ferromagnetic objects Bed rail and vail bed entrapment Medical gas usage. Major Types of FMEA.

When performing a Design FMEA you begin by defining the system hierarchy or the breakdown of all the individual components of your product. 1 DFMEA Design Failure Mode Effects Analysis which is used during the product design stage. It is a step-by-step way to identify all possible failures in a certain design product process or service and study their effects.

Before deploying existing strategies or products in new capacities. Rationale for FMEA in Healthcare If FMEA were utilized the following vulnerabilities might have been recognized and prevented. Many organizations use FMEA as a tool to put their designs and processes under scrutiny.

When conducting FMEA on an existing process consider selecting a process that is known to be problem -. Process FMEA Process FMEAs PFMEA are used to analyze and maintain process control objectives. FMEA stands for Failure Mode and Effects Analysis.

Use event-based simulation approach Step 3 worksheet Step 4. A Design FMEA DFMEA focuses on potential failure modes of products caused by design deficiencies. Designing simulation to support FMEA 5 Event-based simulation design 5 Step 1.

FMEA is a systematic set of activities intended to help a designer or engineer to analyze the design of a system product or process to assure that to the extent possible potential failures their associated causes and their potential effects have been considered and addressed. Design Failure Mode and Effects Analysis DFMEA Gain a working knowledge of the FMEA tool as it applies to product design.

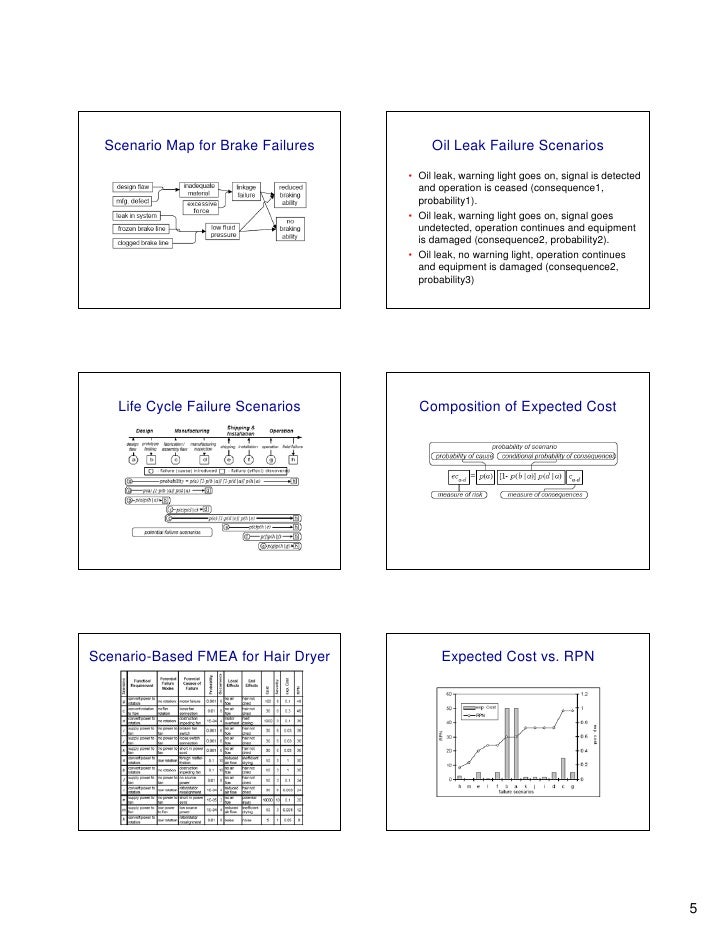

Comparison Of Scenario Based Traditional Fmea Download Table

A Partial List Of Fmea Publications Download Table

Fmeaa Sheet Developed From Diagram Partial View With One Invented Download Scientific Diagram

The Basics Of Fmea Semantic Scholar

Table 4 From Scenario Based Fmea A Life Cycle Cost Perspective Semantic Scholar

Pdf Scenario Based Fmea A Life Cycle Cost Perspective

Dfmea Complete Guide To The Design Fmea Iqasystem

Pdf Scenario Based Fmea A Life Cycle Cost Perspective Semantic Scholar

Failure Modes And Effects Analysis Fmea For The Flood Prone Area Download Table

The Consistency Analysis Of Failure Mode And Effect Analysis Fmea In Information Technology Risk Assessment Sciencedirect

Example Of A Failure Scenario Produced Using An Fmea Of Underground Download Scientific Diagram

Comments

Post a Comment